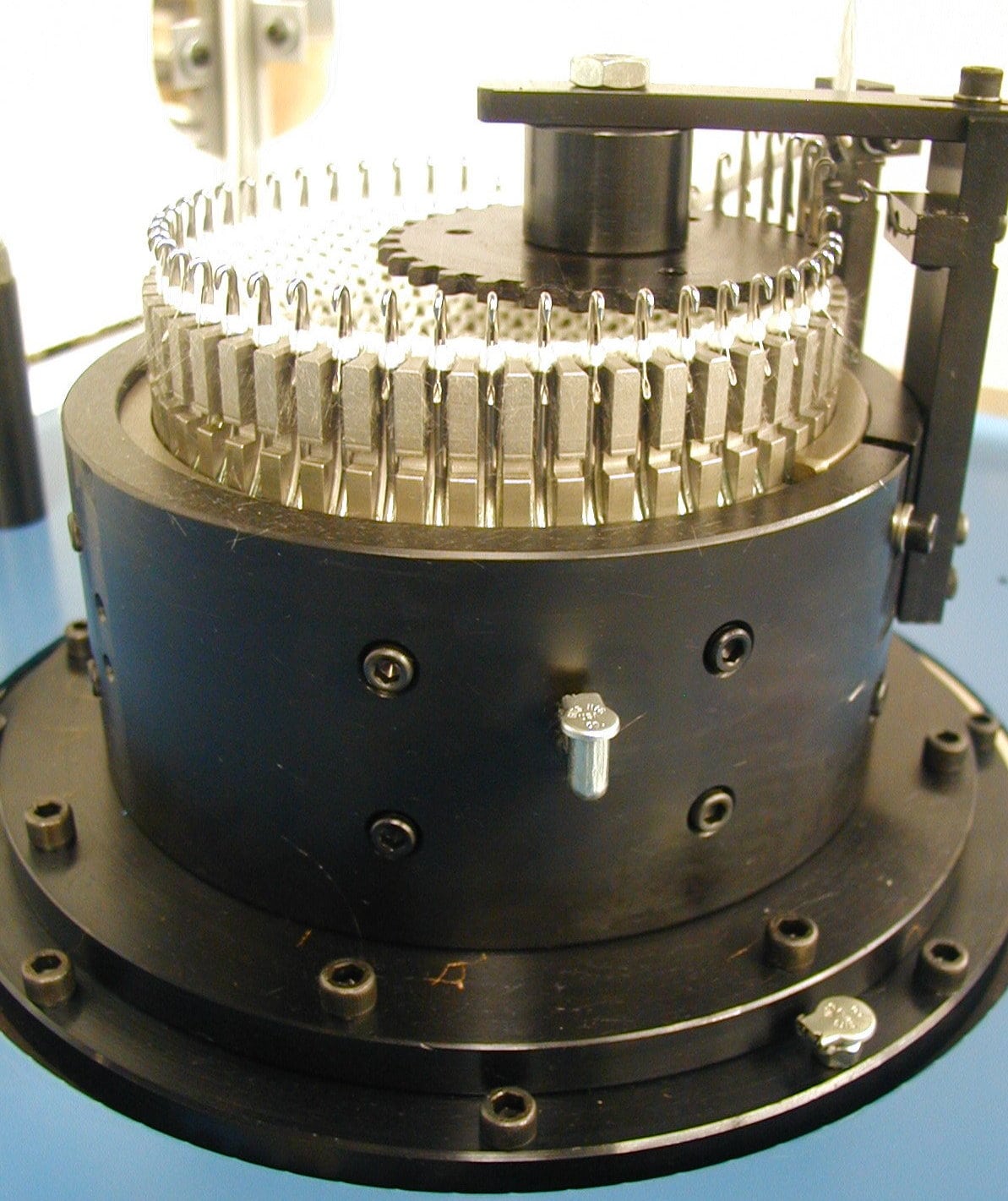

Model LX96 Multi-Feed Circular Weft Knitting Machine

Description

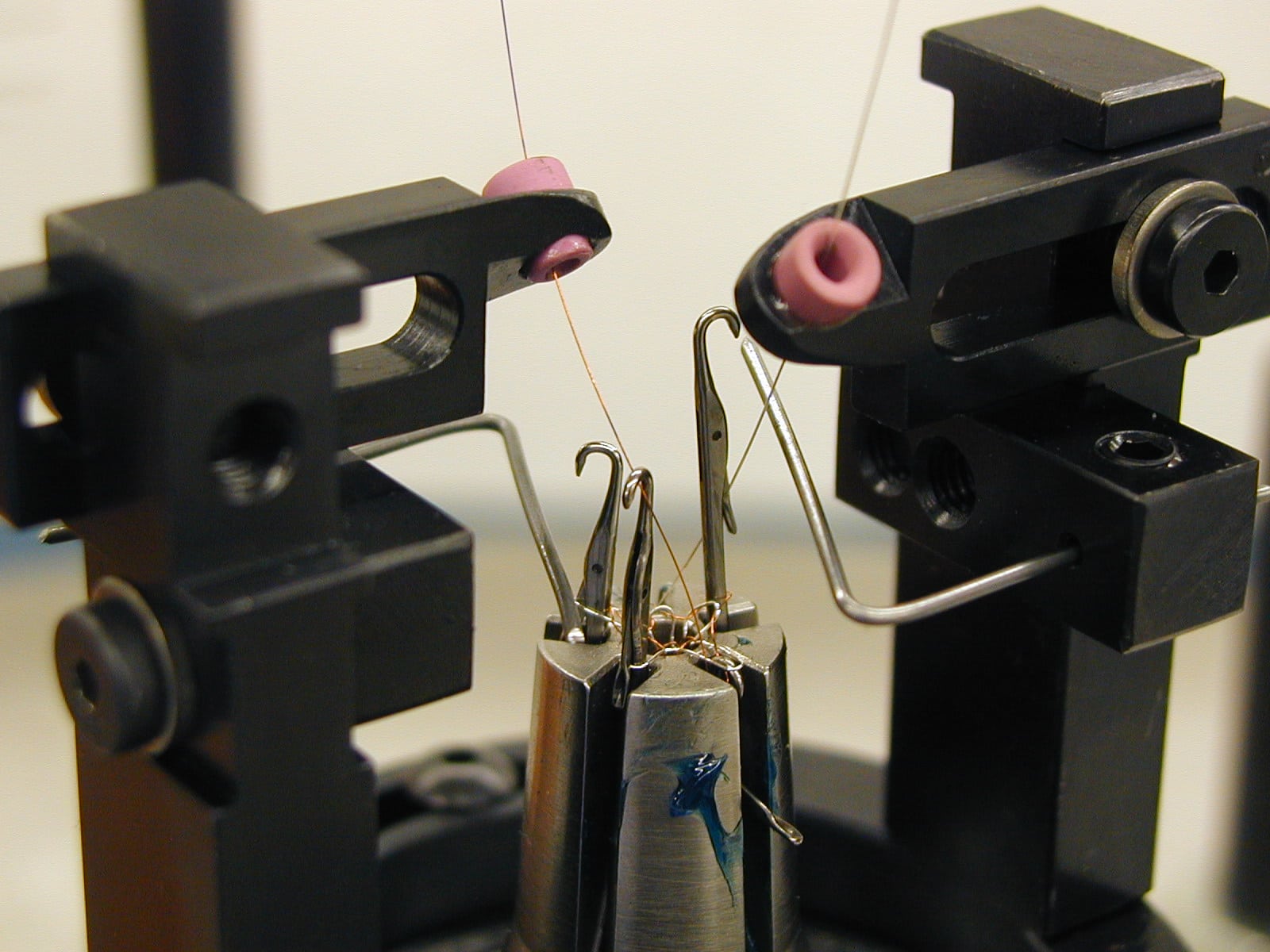

Single, Two or Three Feed, Circular Weft Knitting Machine

LAMB’s Model LX96 circular weft knitting machine is designed to knit either round or tubular flat jersey materials between 1/16″ to 5″ (1.5mm to 127mm). These machines are available in different configurations to produce the specified knitted mesh. The LX96 is primarily used in industrial applications, such as filtration, hose reinforcement and gasketing.

This machine is available as a single feed OR as a two or three feed machine. The LX96 machine is extremely versatile as it can be used to knit either round or tubular flat, single or multi-color materials as well as for knitting simultaneously around a core (filler material). This machine can also accept Pattern Wheel components to mechanically select needles for tuck and float knit features, as shown in the video link provided on this page.

The LX96 machine is available with the following options:

- Power Feed

- Hardened Take-Down Rolls for Tubular Flat materials

- Take-Down Wheel (Capstan) for Round materials

- Precise Take-Down mechanisms

- Precise Stitch Control

- Roll-Up Attachment

- Stop-Motion Detection

In addition, the LX96 machine can be retrofitted with larger platforms to accept cylinders up to 6-inch OD and for knitting fabrics as large as 5-inch flat width.

For any questions please contact us.